What tools/materials do I need?

Various things are necessary for the production of foil cones. You can buy some. Others you have to make yourself. A listing of the sources of supply for the purchased materials is provided here to find.

Felt-tipped pens are required to color the foil cones. However, not all felt-tip pens have proven themselves in the same way. highlighter e.g. B. the cones do not stain sufficiently. This makes it difficult to see the arrows in the targets at longer distances. I have had the best experiences with permanent markers from Edding. A small disadvantage of edding pens is that they almost always color opaque and opaque. If you want transparent yet bold colors, you should also try other permanent markers.

Good scissors are part of the basic equipment. Usually any household scissors will do. In a YouTube video I had received the recommendation to use scissors from the medical field. Such would cut particularly well. Also true. So I bought these scissors. It's really very good. However, any other household scissors will also do their job here.

I use a cutter knife so that the silicone hoses can be cut off exactly straight. At first I used scissors. However, I had to realize that I was not able to cut the silicone hoses exactly straight with the scissors. In addition, it is much faster with the cutter knife if you want to produce a few pieces of hose in stock. To do this, you simply place the hose next to a reference piece and can cut off your pieces to the correct length without having to measure them. The cutter I use has a slanted blade. This makes it easier to cut off the hose.

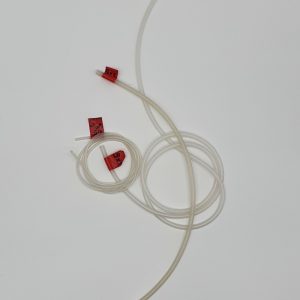

The wrapping aid is a central tool for the production of foil cones. In principle, any type of cone can be used as a winding aid. I experimented with different variants and decided on curtain rod end pieces. They are made of metal and are therefore extremely durable. They are cheap to buy and the material and shape are ideal as a changing aid. There is more detailed information about this changing aid here.

The cutter is of central importance if foil cones are to be manufactured precisely and with repeatability. In principle, a film cone can also be cut off with scissors. I started with that. However, the foil cones produced in this way cannot be produced exactly and with repeat accuracy. Only the use of a cutter ensures precise and repeatable results. Unfortunately, as far as I know, you can't buy such a tool. So I developed and built it myself. I know exactly how that works at this point explained.